|

Flex duct and Ductboard

• Insulation is part of the duct itself

• R-4.2 insulation is most common on flex duct

• R-6, R-8, and R-11 flex duct is also available

• Ductboard is typically made from R-4.3

• Ductboard also available in R-6.5

Fiberglass Duct Liner (for metal ducts)

• Used to line the inside of rectangular metal ductwork

• Made of specially-treated, rigid fiberglass insulation

• Typical R-values are 3.6, 3.7, and 4.2 per inch

• Available in ½, 1, 1-½, and 2 inch thicknesses

Fiberglass Wrap Insulation (for metal ducts)

• Used to cover outside of ducts located in unconditioned spaces

• Typical R-values are R-3.6, 3.8, and 4.1 per inch

• Available in 1-½, 2, 2-¼, and 3-inch thick rolls

• Available with or without a vapor barrier (an outer covering of reinforced foil)

• Insulated better than duct liner

Remodeling Scenarios

Existing construction

For existing duct work, there are basically three options for improving any given portion of ductwork. Depending on where the ducts are currently located, their present condition, and the costs involved, you can:

• Relocate the thermal envelope

• Relocate the ducts

• Seal and better insulate the ducts

While it is generally preferable to locate the ducts within the thermal envelope, it may be physically impossible or very expensive to alter the location of the thermal envelope or the ducts themselves. If re-location is not possible, ducts should be sealed with mastic and possibly better insulated. This can be a very worthwhile measure even if it is necessary to remove and reinstall the existing insulation.

How to vent a microwave outside?

Learn how to do it on this page.

Humidifier is in really bad (corroded).

You can learn how to replace it on this page.

Hvac ductwork attic pictures.

You can see them on this page.

Hvac mounting in attic.

Learn how to do it on this page.

Install ceiling register duct.

Learn how to do it on this page.

Issues with blocking fresh air intake home.

There are not too many issues will apply. Get more info on this page.

Kitchen vent installation guide.

Get it on this page.

Loss of sleep banging in heating pipes.

Learn how to fix it on this page.

Loud banging and tinkering noise in walls reason?

Learn how to fix it on this page.

May thermo ply be used as an alternative material in a return air plenum?

Yes.

Manual instructions for ducting.

Get them all on this page.

Microwave ductwork for dummies.

Com’on, you are not one of them… Learn how to install it on this page.

Microwave exhaust duct work.

Learn how to run it on this page.

Noisy ductwork expansion contraction.

Learn how to fix it on this page.

Noisy forced air ducts.

Learn how to fix it on this page.

Range hood vent duct installation.

Learn how to do it on this page.

Rectangular duct offset formula.

Find it on this page.

Sheet metal cross broke plenum.

Learn how to do it on this page.

Sheet metal formulas for offsets.

Find it on this page.

Should you place air returns in a kitchen.

No.

Ticking noise in house.

Learn how to fix it on this page.

Ticking noise in water pipes next to boiler.

Learn how to fix it on this page.

Ticking noise split system air conditioner.

Learn how to fix it on this page.

Ticking noise when furnace operates.

Learn how to fix it on this page.

Ticking sound out of floor register.

Learn how to fix it on this page.

Ticking while furnace is on.

Learn how to fix it on this page.

Tips on ductwork installation.

I have tons of tips in my DIGuide book.

Water heater fresh air intake.

Learn how to do it on this page.

Water heater combustion air.

Learn how to do it on this page.

Weird noises coming from the floor vents in certain areas.

Learn how to fix it on this page.

What makes a ticking sound in the house?

Learn what makes a ticking sound and how to fix it on this page.

What kind of ductwork do I need to install an external kitchen exhaust fan?

Sheet metal ducts.

What kind of duct work for a bathroom fan?

The best one is 4” insulated flex.

What should I consider when I install air return duct in a new basement?

Get all the info right here on this page.

What’s that random knocking sound in the vent pipe?

Learn how to fix it on this page.

Where to install ceiling return air vents?

If it multiple vents then in every bedroom and in a hallway.

Where to run ductwork in a two story with no basement?

In the attic, or you can drop ceiling on both levels.

Where to place cold air returns in a basement?

8” off the floor. Get more info on this page.

Why is my furnace duct work popping with no heat on?

Learn why and how to fix it on this page. |

|

|

New Unit Trouble (Condensation in Attic)

On this page you can find a solution to your problem!

Read the question, but do not skip the answers and feedbacks if it seems that your issue is a slightly different. The most of the solutions are the same and you just have to analyze information on the page and adapt it to your particular case.

If there are still no a solution in sight, please go to the Parent Page and find the other more suitable to your case page. However, I would recommend you to read them all, it will definitely educate you to the point that you won't need any additional advice from any third party!

All the secondary pages, just like this one, are free of charge and represent clear solutions to high/low humidity problems!

Question

Problem: Newest (11-month-old) Amana System (model # ARUF363616BA) is condensing profusely when I turn the temperature below 75-77.

Unit Location / Details: Unit is in an attic, there is ventilation to the outside and it is on the third story of a house in NE Florida, so it gets HOT up there. I purchased this home 7 months ago and before purchasing it the person who rehabbed and sold the house had a new Amana 3 ton system put in, the previous unit was a 2.5ton and had gone belly up.

Question: The Company that installed it (they came out and had a look at it after I let them know about the problem) has told me that the issue was warm air intrusion that we found when looking at the system. There was a crack in the flex tube intake about the size of a pencil eraser that was patched. The problem is that the unit is still condensing on the bottom of the unit and filling up the emergency drain pan even after that small hole was patched. After I let them know, the issue was still occurring they said the next step would be to replace the flex tubing in the attic and go from there.

My Theory: So after crawling around in the attic, calling Amana and getting them to send me a copy of the instruction/owners manual, and doing some reading on these forums here is my thoughts and I would love to know if you think I am close, way off-base, or just missed the mark.

Flex Tubing. The flex tubing in the attic is old, about 1/3 of is was replaced when they put the new system in, but the other was left, it is about 22 years old and there are some small leaks in it that I have tried to patch. The unit is still under the 1yr installation/parts warranty, is it not standard to replace flex tubing that is old/damaged when installing a new unit?

Return Air. Alright so according to my Amana installation manual (model # ARUF363616BA) I need between 375-425 CFM per ton for my unit to have the proper air supply to run multiply that by 3 tons and I got 1125-1275 CFM needed to run the system. The distance from the return opening to the unit is about 18 feet and it makes 2 90-degree turns before reaching the unit, it is also a 12 inch return. Looking around the site it looks like in rough numbers for a short return a 12 inch duct will return about 600cfm, a 14 inch about 900 cfm and a 16inch about 1400 cfm on a short return. Am I wrong to assume that 18 feet with two right turns is not a short return and my unit may be starved for air? The company that put it in said that 12 were more than enough and a 14 would not give me enough static pressure for the unit.

So the unit is sweating like crazy and that is the overview and my thoughts. I would really appreciate some feedback and any suggestions as far as what I should have done, this unit was the only thing new with this house and the 1 thing I thought I would NOT have to worry about (replaced the roof, hot water heater, windows, etc.) but such is life.

Thanks again for your comments on this thread and the great resource that these forums are.

Overview of the system, please bear with me. I pasted 3 pictures together so you could see the entire unit so it looks a bit odd but should give you an idea of the layout. Keep in mind from the return air source (on the far right, another picture of it below) to the far left side of the unit were the air intake is approximately 15-18 feet.

Air intake/return source. As you can see, this is a 12inch intake which should give me about 600CFMs about 1/2 of what the 3 ton system needs (please let me know if I am incorrect).

In the attic this is were the return air comes through that 12inch flex tube pictured above, is it just me or does that kind of bend take my 12inch return down to a 9-10?

All right, there you have it, I hope this is a decent first time post, I think I followed all the rules and hopefully someone has a little time to let me know their opinion on this. I am a big DIYer but electrical work and HVAC units are something I leave to the pros, just not sure if this particular pro has my best interests in mind seeing as I am still under warranty.

Thanks again,

Tom

Answer

12in flex will only flow around 625cfm,(on a good day)this is not taking into account, length, friction loss, bends, kinks, est. at the very least it needs to be 16in if not 18in.Seriously though, you need to find some1 that knows what their doing.

Feedback

So, I ended up going with the 2nd contractor I met with and he redid the old return, which was a 12" to a new box that returns 16".

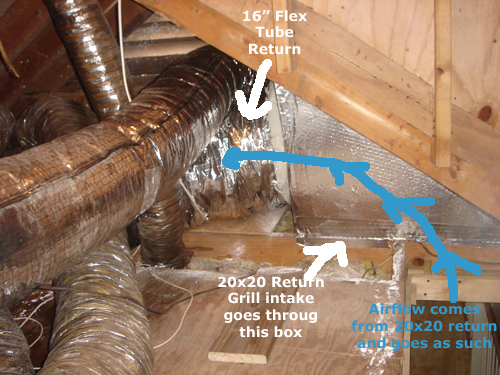

At the smallest point of the return intake the rectangular space is 9x18 so I believe I have at least close to what the system needs, take a look at the work below.

So I had that put in by a guy that I got a good vibe from and came well recommended, he checked my levels on the outside of the house, checked the P-trap on the drain line etc.

The vents are pushing quite a bit more air out now and once we turned on the unit the house cooled down, which feels amazing since it has been over 80 in the house for the last week as I tried to dry out the system in the attic.

So he left today around 2, after I got back from meeting with a couple clients I went up in the attic to clean up the shop vac, etc from cleaning up the water mess from before and low and behold......

Not sure, how well that picture shows up but basically the entire unit is sweating/condensing heavily, along with the "hood"? (Area where air exits the furnace and goes into a box, then into the flex duct).

On top of that, the flex duct runs are sweating on the bottom as well.

I left a message for the contractor who redid the return as he said the unit might sweat just a little bit but once the weather cools off and the heater gets turned on (about 2-3 months from now) that the system will dry out and not condensate again next year.

After putting my family through a week of 80+ degree inside temp and spending a considerable amount of money (not supposed to discuss prices but it is more than both our car payments) I feel as if I am at square one, or close to. The unit is running much better but if I drop the temp setting below 77 my attic starts to get VERY WET.

If anyone has an idea I would love to hear it.

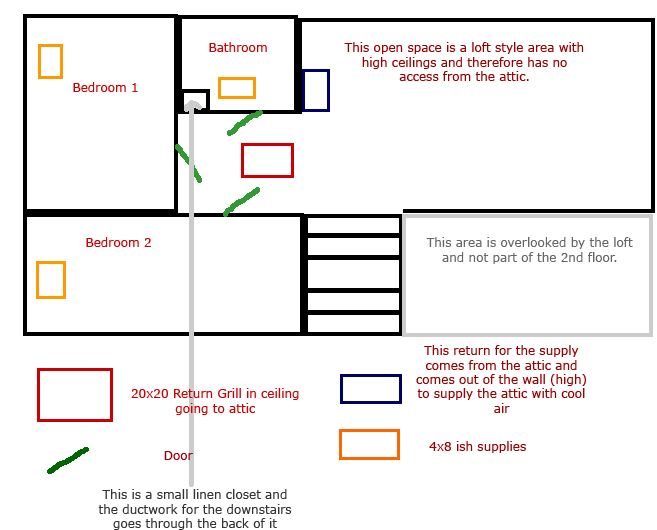

The 20x20 return grill was left, the duct board supply inlet was replaced and modified with the return box leading into the 16 inch supply.

He did not check the CFMs or reset the fan; he said the supply outlets are sized correctly but that the deteriorating flex duct in the attic was casing an issue. I will be having the p trap installed close to the air handler, should that be upstream or downstream of the T float safety valve.

I tried having the wife shut off the fan while I was outside by the drain line to see if the water "rushed out" and there was no change. The supply plenum sweats a little but not a lot, it is the first 4-5 feet of the supply lines that seem to be wet.

Answer

IMO 16" flex is not good for 1200 CFMs and a 20x20 return grill is way short. As suggested above you need a properly sized supply. I have seen horizontal pans on some systems that required a piece of metal about 4" tall installed on the lip of the condensate pan. It is required on horizontal installations. Water will tabulated in the pan and spit over the lip especially if the static pressure is high due to several factors one being an inadequate duct system. It usually comes uninstalled and a lot of installers forget or don't know to install it. This may or may not be applicable in your case. Do you have a model number and brand of your air handler?

|

|

Feedback

All right sorry if this post was a staging ground for contention.

Pics from the inside of the unit on the way.

First pic of the inside of the unit, had my 4th pro come over today and told him I was not satisfied with the "bad duct work" solution and asked him to take a look inside the unit to see if it had been installed correctly. His response was "everything looks ok to me but I need to get going"

I am glad I watched him take off the 2 panels and reminded him he had my screws in his tool belt as he left....

Anyway 2 pics from the inside of the unit.

And another pic, the coils are sweating quite a bit but it looks to me that the "spit guards" are installed correctly, let me know if I am mistaken or if there is anything obvious this guy should have let me know about before he answered his phone and then took off without replacing the dissembled unit.

The pan when the unit was opened had very little water in it, the downhill side was moist but there did not seem to be any drainage issues, I was expecting to see it close to full. My standard thermostat does not (to my knowledge) allow fan speed reduction. So I am not sure if it is pulling that water right off the coil instead of letting it drip down, and this last pro was far to busy to do any tests even though I was more than willing to pay for his time, he had better places to be.

With this kind of service in this area, I am tempted to open a business, anyone in this area with some customer service and expertise I think could make a killing.

Sorry if there was something that came across the wrong way, clarification time.

I am aware that the amount of water the unit will produce by conditioning Florida air is significant and water will be a flowing through the 3/4 pvc drain pipe that comes OUT OF THE UNIT.

The PROBLEM is that the "cabinet" / "furnace" / "big air conditioner box" is condensating heavily (about a gallon an hour) this picture should clarify I am sorry if I confused people early on in this post. The blue (crudely drawn) represents big droplets of water that drip down into the large metal "safety pan" under the "cabinet" AND off the supply box and the first 5-6 ft of the supply ductwork therefore getting my attic floor and additionally bedroom ceiling wet. If you look closely between the yellow energy sticker and the yellow/white sticker in the bottom left of the picture you will see big water droplets on the side of the unit which are much more abundant on the bottom.

Unless I am crazy the entire cabinet should not be sweating if I turn the temp on the thermo below 80 and the supply box/plenum and first 5-6 feet of the flex duct supply should not be condensating/dripping water into my attic should it?

About the RH it is around 70-80 this time of year and inside it is now 70-80% I am not sure what the typical inside home RH is but things feel really damp/sticky inside.

I was told to keep the fan on 24/7 and when it gets turned off even with the temp set at 80 the unit drips like crazy so the fan is on constantly which may affect the humidity?

Had a new p-trap put in right inside, interestingly he said the outside p-trap would need to be removed (which I did). So here is a picture of the new primed p-trap.

Took a look inside, he said that it looked a little dirty for a 11 month old unit but that it was not that bad and did not warrant a major cleaning and he vacuumed out the dirt in the bottom left of the 2nd picture and cleaned the top coil a little bit with a shop vac. Although afterward it looked pretty close to the way it looked in these pictures.

I asked him about this and got laughed at, said it was the most foolish thing he had ever heard and that it was obviously the supply ductwork that needed to be replaced.

Due to the way the house was constructed (the return grill is located on the 2nd (top) floor in a hallway/opening area. There is really nowhere to put another return unless it is put in one of 2 bedrooms which 2 pros told me was a bad idea because it just sucks up the recently conditioned air from that room and cycles it right back into the system.

Here is a small (poorly done) diagram of the upstairs of the house, all orange (supply) vents come out of the ceiling

I also forgot but there is a door on the linen closet.

I would hope the bedrooms have larger than 8x4 supplies.

Answer

I think you are goanna have to bite the bullet, and get somebody to do a load calc. Or, you can do your own. Look at the top of one of the pages here. It's not free but, it'll take the guess work out.

After that gets done, it's time to see what size duct you're supposed to have.

Sounds to me like you got hacked on this whole system, sorry to say.

|

|

Feedback

Here is a picture of the grill, it fits a 20x20 filter.

It feeds into a duct board box that is pictured here.

The box was built as the 16-inch flex duct would be crammed down at an angle due to the pitch of the roof being close by the grill and have to much of an angle so the box was built to provide the full airflow from the 20x20 into the 16" flex.

Added poorly illustrated picture of airflow etc.

That return can looks like it follows the pitch of the roof. Starts at 16", and goes to nothing.

I'll bet yah, there still isn't enough RA.

This picture shows the 16" flex duct it has no major bends/kinks/bunches as it returns to the intake portion of the unit, it does run for about 14 feet and have one 60degree or so bend when it does, along with the long bend to get it inline with the unit. The 16" flex goes from the return box all the way to the unit; it does not go into a smaller section of flex.

Four-minute video with an overview of the entire system/problem.

Forgive the crappy quality and sound fluctuations, hopefully this clarifies things.

|

Answer

Most of your supply ducts are down to about half capacity due to being kinked/not supported correctly.

Don't move the trap. Just have the pipe insulated. Here in Houston, the first 12' has to be insulated ,just for this reason. It's really hard to tell over the 'net what exactly the problem is. As you can tell by 13 or 14 pages of replies. Could be the guys you've had out, are right about replacing the supply duct.

Any way you could ask the original owner or service company, what size unit they removed?

Did you live here when the old unit was there. Or has this happened just since the replacement?

I'm thinking they removed a two ton, and went back with a three, only making things worse. You really need a load calculation done, to get headed in the right direction. Everything else is only guessing.

Answer

Water dripping off the unit and plenum can be a few issues. In this set up the water on the flex tells me its shot. Whether it is just shot or undersized, sizing and installing it properly will take care of it. Either way it needs to be done. As far as the return yes marginal. I was curious about the td because I am willing to bet its pretty high.

1| 2| 3| 4

|

|

|