| Related Pages: |

|

|

Finished Basement Edition

Doing ductwork installation sounds like a job that must be done by a professional. You may be surprised to know that by following my simple instructions, you can install your own ductwork in no time.

|

|

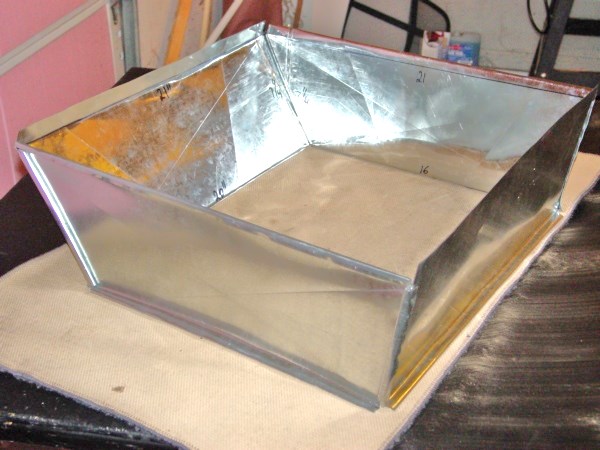

Installation in Pictures

Some of the visitors of my website are very sophisticated DIY-rs. They don’t need long and detailed explanations; they just want to see how it supposed to be done so they can do it!...

|

|

Kitchen Remodeling Edition

When it comes to the ductwork, kitchen remodeling requires resolving some of the most important issues, which could... |

|

Dollar Guide

This page is designed to help a homeowner with some simple issues that can arise in his/her DIY ductwork installation project.

|

|

Extending HVAC ductwork

When people are planning to change their layout of ductwork, finish a basement off, kitchen remodeling or other renovations they are usually buying my books or paid pages, because there is no other place to go. However, not all of them! Some of them are looking for help on Forum websites. Below you can see one more example of it...

|

|

Have you ever wondered what kinds of tool an ordinary residential ductwork installer carrying in his pouch?

On this and on the following pages you can see a complete set of all necessary tools that I’m usually carrying in my pouch, keeping in my toolbox or having in my van.

|

|

Ductwork Installation Tips and Tricks

Every profession has its own tips and tricks and the profession of the ductwork installer has them as well, a lot of them! On this and on the next pages I would like to introduce seventeen topics dedicated to this issue.

|

|

49. Venting* – the chapter is divided in two parts and describes all possible cases of installation and termination of the

venting for 80% and 90+% furnaces. venting for 80% and 90+% furnaces.

The chapter has 66 pictures; 34 pages*. $2.69 (Instant Access).

*Article:

Venting & Draining Condensing Gas Furnaces

Laundry and Condensing Furnaces Don't Mix.

SIMPSON DURA-VENT SIZING HANDBOOK, pdf file. Z-Flex.

On 12/18/2014 text of this chapter was significantly modified and improved. Two photos were added. |

|

DuctWork Installation Problems 1

|

|

In my Ductwork Installation Guide e-book you can read about entire process of ductwork installation from start to finish and even find several chapters with rare and unusual cases. However, it is next to impossible to include in this e-book all the challenges an installer meet in virtually every house. Every time when electricians and/or plumbers were in the house ahead of you they easily create a whole host of issues!

On this and on the following pages I'll show you many of these cases and explain how this or that problem was created and how it was resolved.

If you at your work have similar kinds of challenges feel free to contact me below. Also, if you would like to know when the next ductwork installation problem will be published here on my site you can subscribe to the alerts below.

|

|

South Lyon, MI

Builder: Palazzolo, Lot #23

12/15/2014

At first this problem was created by architect or/and carpenters. They not just placed a joist on the I-beam, but for no reason at all even nailed a header in every single joist space - above this monumental structure is a hallway...

The plumbers in this house did the right thing: they placed the gas line aside. In the previous and in the next house they ran it right through the middle.

However electricians didn't follow the suit and pulled their wires right through the middle, so now, I hope, they will learn something...

And another problem, even two! They placed the second joist too close to the first one and the gas line won't let you install the blocker in place, so it should be installed first.

The similar problem with the heat runs - the joist is too close, it's why instead of round 45* I used round-to-oval 90* boots.

The same heat runs after they jumped above the I-beam

Again, in the best case scenario the wall upstairs should be placed somewhere in the middle between joists, but not too close to one of them. It's why in the first case for the "straight shot" I used an oval 90* and round-to-oval end boot and in another round-to-oval 90* boot for the "jumper".

|

|

43. Installation of Heat Runs – the chapter covers the heat runs installation in the basement and deals only with all  possible cases of the “straight shot”. possible cases of the “straight shot”.

The chapter has 112 picture; 65 pages*. $3.41 (Instant Access).

On 10/12/2014 text of this chapter was significantly modified and improved. 7 photos were added. Examples of Pulte Homes ductwork installation were also added to this chapter.

|

|

South Lyon, MI

Builder: Palazzolo, Lot #21

12/17/2014

This bath box would be relatively easy to hook up if the guy who was sent to install furnace temporarily would does so, but he doesn't. First off, he placed the furnace about 4' away from the projected spot, then he ran PVC pipes right below it and finally he glued them all... This bath box would be relatively easy to hook up if the guy who was sent to install furnace temporarily would does so, but he doesn't. First off, he placed the furnace about 4' away from the projected spot, then he ran PVC pipes right below it and finally he glued them all...

So, didn't have a choice, but connect it to the plenum the way you can see it in the pictures above and on the left.

|

|

Sterling Heights, MI

Builder: Greenstone, Lot 39

12/23/2014

I don't know why a plastic waterline should be isolated in the cold air return, in my opinion it even would help in the case of fire, but according to code it must be isolated and I asked plumbers to move it a bit.

Then I isolated it with some thermo-pan.

|

|

34. Sheeting (Panning)* – the chapter covers almost all possible cases of the joist's panning with a wide variety of  uncommon cases, presents how to deal with penetration of the wires, copper and PVC pipes. uncommon cases, presents how to deal with penetration of the wires, copper and PVC pipes.

The chapter has 59 pictures; 29 pages*. $2.50 (Instant Access).

Summary Report for:

47-2211.00 - Sheet Metal Workers

On 12/28/2014 text of this chapter was significantly modified and improved. One picture added. |

|

Macomb, MI

Builder: Pulte, Lot #1

12/16/2014

It's pretty bad when in your company some installer doing only Rough-in! They have no idea what should be done in the basement. And here is an example of such installation.

As you can see it in the picture, oval 90* is set too high in the 12" tall joist space and connection to the take-off is impossible to do.

So, I cut a strip of the bond, pulled oval 90* down and made a connection.

|

|

Berkley, MI

Builder: Oliver Construction

01/09/2015

OK, here is a little test: describe what kind of issue you can see in the pictures, who is at fault, and how this issue was resolved. Email your answers below. In return I'll email you any paid page up to $3.00 value absolutely free! OK, here is a little test: describe what kind of issue you can see in the pictures, who is at fault, and how this issue was resolved. Email your answers below. In return I'll email you any paid page up to $3.00 value absolutely free!

The same house, another problem and the same test... The same house, another problem and the same test...

|

|

Bloomfield twp., MI

Builder: Dimmena

02/10/2015

The problem in this case is in the house design. Snow from three roofs sliding down to one spot and piles up to 4' - 5' completely covering furnace exhaust & intake.

In order to resolve this issue I ran both pipes up in the stud cavity and out through the wall.

|

|

49. Venting* – the chapter is divided in two parts and describes all possible cases of installation and termination of the

venting for 80% and 90+% furnaces. venting for 80% and 90+% furnaces.

The chapter has 67 pictures; 34 pages*. $2.69 (Instant Access).

*Article:

Venting & Draining Condensing Gas Furnaces

Laundry and Condensing Furnaces Don't Mix.

SIMPSON DURA-VENT SIZING HANDBOOK, pdf file. Z-Flex.

On 04/10/2015 text of this chapter was significantly modified and improved. On 05/28/2015 one photo was added. |

|

Novi, MI

Builder: Healy Homes

04/14/2015

In this case a rougher, a naturally born idiot, dropped the oval 45* in the very narrow look-out without extension, it's why it ends up right behind the joist. So I had two choices: cut the drywall, remove the bath-box (stack-head) and extend it or cut out the joist.

A superintendent choose the second option...

|

|

|