| Related Pages: |

|

|

Finished Basement Edition

Doing ductwork installation sounds like a job that must be done by a professional. You may be surprised to know that by following my simple instructions, you can install your own ductwork in no time.

|

|

Installation in Pictures

Some of the visitors of my website are very sophisticated DIY-rs. They don’t need long and detailed explanations; they just want to see how it supposed to be done so they can do it!...

|

|

Kitchen Remodeling Edition

When it comes to the ductwork, kitchen remodeling requires resolving some of the most important issues, which could... |

|

Dollar Guide

This page is designed to help a homeowner with some simple issues that can arise in his/her DIY ductwork installation project.

|

|

Extending HVAC ductwork

When people are planning to change their layout of ductwork, finish a basement off, kitchen remodeling or other renovations they are usually buying my books or paid pages, because there is no other place to go. However, not all of them! Some of them are looking for help on Forum websites. Below you can see one more example of it...

|

|

Have you ever wondered what kinds of tool an ordinary residential ductwork installer carrying in his pouch?

On this and on the following pages you can see a complete set of all necessary tools that I’m usually carrying in my pouch, keeping in my toolbox or having in my van.

|

|

Ductwork Installation Tips and Tricks

Every profession has its own tips and tricks and the profession of the ductwork installer has them as well, a lot of them! On this and on the next pages I would like to introduce seventeen topics dedicated to this issue.

|

|

49. Venting* – the chapter is divided in two parts and describes all possible cases of installation and termination of the

venting for 80% and 90+% furnaces. venting for 80% and 90+% furnaces.

The chapter has 66 pictures; 34 pages*. $2.69 (Instant Access).

*Article:

Venting & Draining Condensing Gas Furnaces

Laundry and Condensing Furnaces Don't Mix.

SIMPSON DURA-VENT SIZING HANDBOOK, pdf file. Z-Flex.

On 12/18/2014 text of this chapter was significantly modified and improved. Two photos were added. |

|

DuctWork Installation Problems 2

|

|

In my Ductwork Installation Guide e-book you can read about entire process of ductwork installation from start to finish and even find several chapters with rare and unusual cases. However, it is next to impossible to include in this e-book all the challenges an installer meet in virtually every house. Every time when electricians and/or plumbers were in the house ahead of you they easily create a whole host of issues!

On this and on the following pages I'll show you many of these cases and explain how this or that problem was created and how it was resolved.

If you at your work have similar kinds of challenges feel free to contact me below. Also, if you would like to know when the next ductwork installation problem will be published here on my site you can subscribe to the alerts below.

|

|

South Lyon, MI

Builder: Healy Homes, Lot #5

06/29/2015

The distance between the last joist and the bottom plate in this basement is 3", but between the same joist and concrete wall is only 2 ½"! The carpenters who built this condo definitely have less brain cells than their moms when they refused that abortion options...

So, in order to make it work I used a 10" x 4" oval 90* boot.

Removed the sleeve and blocked the opening on the side.

Then cut out a new oval opening in the bottom flush with one side, tapped a sleeve.

My co-worker made another boot from a piece of sheet metal and also cut in a sleeve.

Nailed my boot and broke some concrete.

Nailed the second boot.

Connected round to oval boots and connected them to the take-offs.

|

44. "Jumper" Installation – the chapter gives a description how to make 45 degree angle from the “elbow”.

Chapter covers all possible cases of measurement, calculation and installation of the “jumpers”. Also the chapter covers several uncommon cases of the “jumper” installation. Chapter covers all possible cases of measurement, calculation and installation of the “jumpers”. Also the chapter covers several uncommon cases of the “jumper” installation.

The chapter has 90 pictures; 46 pages*. $2.50 (Instant Access).

On 04/26/2015 text of this chapter was significantly modified and improved. On 06/27/2015 three more pictures were added.

|

|

Macomb, MI

Builder: Lassalle, Lot #125

07/21/2015

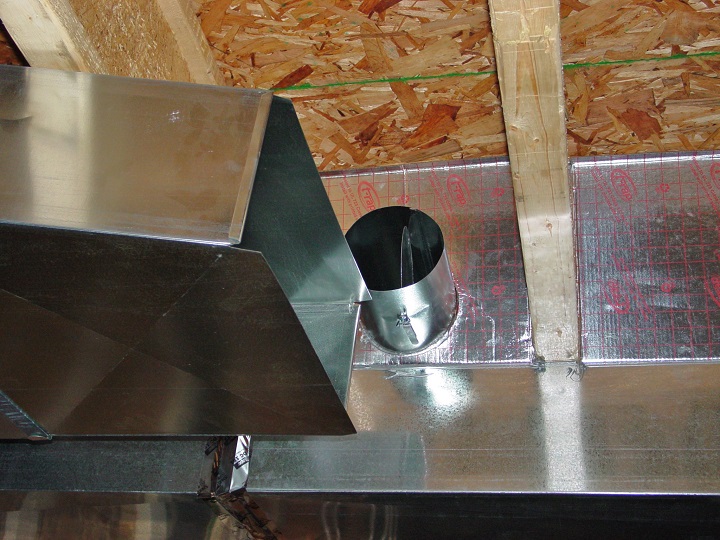

All these heat runs, bath fan exhaust, cold air return and furnace exhaust and intake appears above the cold air return duct and behind the plenum.

So, I extended down one heat (on the left), figured out pipe length for the second one, connected 4" flex and ran it out above the I-beam and made a box for a cold air return.

Installed 3" furnace exhaust pipe and extended intake.

After plenum was set in place I connected both heat runs, finished 3" PVC pipe and ran a combustion air intake.

Also, in the same house I ran a 6" heat through a cold air return and it appears in the place where a transition and next duct should be joined. To resolve this issue I used a round elbow as an offset and inserted a take-off to find its location on the supply duct.

Dovetailed a take-off and joined all parts together. |

|

Rochester Hills, MI

Builder: Newmark, Lot #3

08/04/2015

The problem with this installation occurs because three heat runs should be connected over the cold air return duct and joists changed their direction.

In order to resolve these issues two take-offs were installed between a plenum and cold air return duct and connected to the wall stacks before cold air return duct was mounted.

And here are final two pictures.

|

|

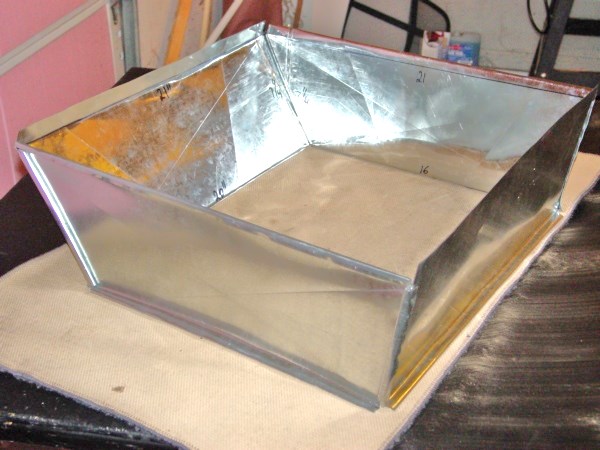

38. Plenum Installation* – the chapter covers all three types of plenums, gives an explanation how to put plenum  together, put a top cap on, cut in a starting transition. After that chapter will explain on how to set up a furnace in relation to the I-beam. together, put a top cap on, cut in a starting transition. After that chapter will explain on how to set up a furnace in relation to the I-beam.

The chapter has 52 pictures; 30 pages*. $2.50 (Instant Access).

Article:

How A Professional Designs A Heating or Cooling System.

On 04/29/2015 text of this chapter was significantly modified and improved.

A link to the International Code added (11/05/2012).

On 06/22/2015 one more pictures was added.

|

|

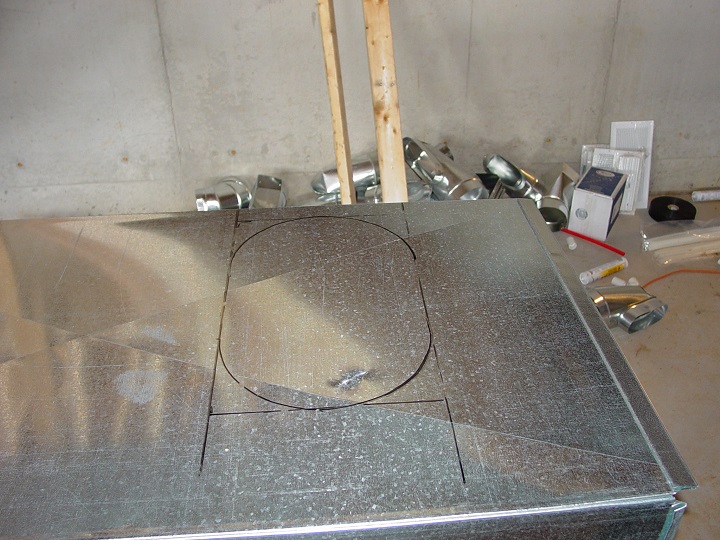

Orion Lake, MI

Builder: Pulte, Lot #37

08/11/2015

A 14" cold air return in this house appears to be oval!

In order to connect this 14" oval pipe to the cold air duct, at first, I made it perfectly oval, took measurements and crimped the pipe.

Placed the co-ordinates on the duct and used a 10" template to make the oval outline. Cut out the opening and installed a take-off for the make up air.

After 14" oval pipe was inserted into the duct I made some tabs on the right hand side to fix the small gap and silicone the connection.

|

|

Pulte Homes Cold Air Returns

Pulte Homes is a nationwide home building company and their way of running heat runs (buy it below) and cold air returns differs significantly from the others. In the e-book above I already covered many aspects of their installations, however in my opinion, the most difficult part aka cold air returns in the basements require a special approach.

If your company is already working for this Builder and you have some experience this page will help you out to learn the best ways of installation.

If you are planning to work for HVAC company or you are the owner of HVAC company that is working for Pulte Homes this page definitely would help you out to learn the best practices and educate your work force.

On the page you can see cold air ducts installations for 8 models - 84 high quality pictures.

Price for this page is only $5.50 and in order to get an instant access to the page please click on the PayPal button below.

Instant Access:

After you have purchased a paid page; PayPal is going to bring you back to my website. In order to see the paid page you have to click on the “Register” button, fill out the form, choose your own Username and Password and click on the “Register” button at the bottom of the form – congratulation, you are now on the page you have paid for!

Important: After you have purchased any Paid page or Download page and PayPal brought you back to my website, the first thing that you should do is to save that page to your Favorites. Then if something goes wrong you always can come back to re-register yourself on my website again.

|

|

Berkley, MI

Builder: Hillan Homes, Lot 28XX

10/01/2015

The installer who ran this oval stack knew that there will be a problem but at least it won't be his problem...

If he would have just a couple more functioning brain cells he could push this oval stack below the joists. Timely performed abortion would also help, but I guess we must respect his mother's choice...

So, in order to extend it below the joists I cut a short piece of pipe, oval it and crimped hell out of it. It doesn't help. Then I used my long nose pliers and crimped it even more.

While inserting this piece into the oval stack I helped myself from the inside.

After that I cut a tab and fastened this piece to one of the joists.

In the last picture you can see how this heat run eventually was done.

|

|

South Lyon, MI

Builder: Healy Homes, Lot 152

12/24/2015

Plumbers. Plumbers are very interesting people, maybe not even people at all! I heard that Homo Sapiens thousands of years ago had sex with Neanderthals. A new study in Nature linked Neanderthal genes to fatty acids that show up in the brains and other tissues of Americans. So the first way that our Neanderthal heritage matters is that it may actually have a bearing on some aspects of our metabolism, our brain function, and more. Let's talk about brain function. Personally I believe that plumbers have double or even triple amount of Neanderthal genes that make their brains functioning differently!

If you need an example just look in the pictures above. Only a Neanderthal could run that PVC pipe right under the oval stack probably because in their caves they had only sewage but nothing even remotely resembling air heating and cooling.

But I still nurturing hope that if I cut their pipes they may learn something.

And here is how it looks like after the connection to the supply duct was made.

Also these geniuses ran the water lines throughout a cold air return. F-k them...

|

|

Royal Oak, MI

Builder: Levine Homes, Lot 20XX

01/08/2016

When Plumbing Company hire a new guy they checking out his IQ, and if its above 85 no chance that this individual will get a position, because he is simply overqualified for the job. The lower, the better!

It's why this particular plumber was smart enough to run the gas line right under the opening in the floor for my heat run.

However this time around I didn't cut anything, but instead of a straight boot used an oval 45 degree floor box.

|

|

|